Chilled Beam Design

Chilled beam is not just the name of a product, it is one of about a dozen HVAC systems a design engineer can apply to meet the needs of the building.

The passive chilled beam concept was developed in 1979 By Farex (the precursor to Swegon) and launched in 1984. In 1987 Farex launched the active chilled beam which today is the most common type of beam. Chilled beams have been in use for over 30 years in thousands of projects around the world.

There is no perfect HVAC system that can meet the needs of all building types in all climate zones. What chilled beam systems can offer are:

- Superior comfort and sound levels

- High Indoor Air Quality

- Simple to design, install and commission

- Architecturally pleasing

- Reduced airflow to spaces compared to conventional VAV systems

- Smaller mechanical rooms

- Reduced ceiling plenums

- Reduced energy cost

- Low maintenance

- Future flexibility (re-purposing)

Chilled beam systems work best in applications with high sensible heat ratios and controlled building envelopes. They work well in all climate zones and in both new and retrofit construction where their small space requirements are beneficial.

Chilled Beam Retrofit in Healthcare Application

Building Applications

Chilled beam systems are typically applied to offices, k-12 schools, institutional projects, laboratories where the airflow level is being set by cooling loads (as opposed to ventilation requirements), hotels and dormitories.

4 Way VAV Chilled Beam in Office Application

Bulkhead Chilled Bema in Hotel Room Application

Pendant Style Chilled Beam in Classroom Application

2 Way Linear Style Chilled Beam in Lab Application

Chilled Beam Design

While chilled beams are common in Europe, they still relatively new to North America. To assist in the application of chilled beam systems, the flowing videos are available to answer questions about design and operation. Additional training is also available and this can provide AIA and PDH credits.

Chilled Beam Concept

This video will give an overview of the chilled beam concept, how chilled beams work and their various types.

Establishing Primary Airflow Rate

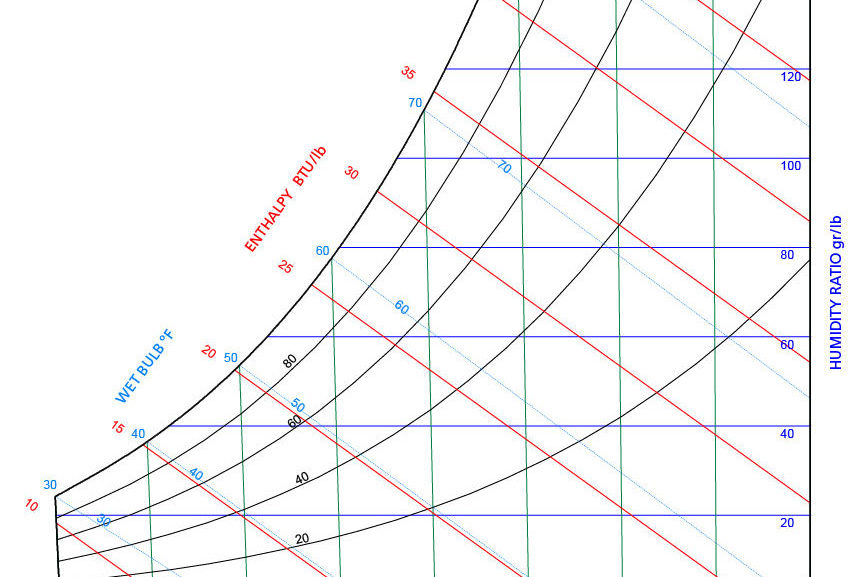

The most critical part of a chilled beam design is to establish proper primary airflow. This video will show what the key parameters are including humidity (dewpoint) control and how to meet those parameters to achieve a good design.

Demand Control Ventilation

Demand Control Ventilation (DCV) is a common method to improve the energy performance of many HVAC systems. Chilled beam systems can also benefit greatly from applying DCV and this video will show the benefits of DCV chilled beam systems.

Chilled Beam Chilled Water Design Strategies Part One

Chilled beams utilize chilled water to provide cooling. Part one will discuss basic chiller plant designs.

Chilled Beam Chilled Water Design Strategies Part Two

Part two of chilled water plant design builds on part one and looks at additional strategies to improve chiller plant performance including waterside free cooling.

Chilled Beam Water Piping Options

This video includes details on what chilled beam installations look like during construction and provides details around hydronic piping including control valve approaches and piping strategies.

Chilled Beam Constant Air Volume Control Strategies

This video will cover control strategies for primary air systems and chilled beam in a constant primary air volume system. Control sequences to deal with condensation are covered in detail.

Chilled Beam Variable Air Volume Control Strategies

Building on the first controls video, this video will delve into the sequences for Variable Air Volume (Demand Control Ventilation) chilled beams including water before air, the air before water and additional condensation management opportunities.