ROOM UNIT

PACIFIC Chilled Beam

Integrated climate beam with cooling, heating and ventilation

ROOM UNIT

PACIFIC Chilled Beam

Integrated climate beam with cooling, heating and ventilation

The Swegon PACIFIC is a high-performance active climate beam that offers enormous flexibility for cooling, heating and ventilation.

PACIFIC fully integrates a capacity module and design module. The design module is designed to allow for easy servicing and access to controls. Return openings can be integrated into the design module to achieve a clean look in the ceiling. The capacity module, which can be selected independently from the design module, provides optimum performance and comfort.

Key Features

PACIFIC | PACIFIC Hi-Cap | |

Primary Airflow | Typical 116 CFM (up to 200 CFM) | Up to 315 CFM |

Pressure Range | Typical 0.5 in WG (up to 0.75 in WG) | Typical 0.5 in WG (up to 0.75 in WG) |

Cooling Capacity | Up to 8872 Btu/h | Up to 13977 Btu/h |

Heating Capacity | Water: upto to 10236 Btu/h | Water: up to 12707 Btu/h |

Lengths | Min. 47 in /max. 120 in* | Min. 47 .8in/max. 119.8 in* |

Widths | Min. 23.4 in/ max. 26.26 in* | 23.7 in |

Heights | 6.4 in – with Ø 4 in air connection 7.4 in – with Ø 5 in air connection 10.9 in – with Ø 6 in air connection | 10.6 in |

Basic Operation

The PACIFIC and PACIFIC HC are active chilled beams with two-way air distribution. The units do not contain a fan of its own but is driven by the pressure and flow generated by a centrally located air handling unit, which means low sound level and excellent comfort in the room. The PACIFIC models are designed for dry systems, i.e. without condensation and therefore do not require any condensate drainage system or any filter. The minimum number of moving parts and lack of filter guarantees very little need for maintenance.

The PACIFIC chilled beams operate according to the induction process. A centrally located air handling unit distributes primary air via the duct system into the plenum of the unit and creates excess pressure. The plenum is equipped with a number of sliding strips that in turn contain a row of nozzles of various sizes. The excess pressure in the plenum forces the primary air through the nozzles at relatively high velocity. When the primary air is distributed at high velocity through the nozzles, negative pressure is created in the space above the built-in heat exchanger (water coil). The negative pressure draws (induces) the room air up through the heat exchanger where the air is treated as required.

LEARN MORE

Induction Process

Active chilled beams utilize the induction process to cause room air to pass through the chilled beam to heat and cool the air and create a comfortable environment.

Induction Principle

The PACIFIC chilled beam has been developed for generating high cooling and heating capacity without compromising comfort. The outlet of the unit is designed to handle large pressure and flow ranges while maintaining the Coanda effect. The result is that the discharged air is kept near the ceiling and mix with the room air and its velocity decreases before it reaches the occupied zone. This provides an excellent indoor climate with low air velocities.

To achieve the best thermal comfort and account for future changes in the space (repurposing) PACIFIC Chilled beams include adjustable nozzles and Anti Draught Control (ADC).

LEARN MORE

Anti Draught Control (ADC)

Delivering a comfortable environment is more than just heating and cooling the space, it requires well distributed air. Swegon Anti Draught Control (ADC) helps change air flow patterns for the best comfort level.

Standard PACIFIC Adjustable Nozzle

PACIFIC nozzle strip adjusted in three positions. L, M and H.

The PACFIC chilled beam’s adjustable nozzles allow the capacity of the chilled beam to be field changed without any tools. The nozzles can be adjusted in 12 inch (30 cm) increments on each side. Each increment has three settings allowing for accurate adjustment to meet the needs of the space now and in the future. To further augment the capacity range, PACIFIC chilled beams come in three models – LF, MF and HF. Each model has its own set of adjustable nozzle ranges.

PACIFIC HC Adjustable Nozzles

Pacific HC Adjustable Nozzles

The PACIFIC HC adjustable nozzles utilize a sliding plate that can be adjusted with a screwdriver.

Anti Draught Control (ADC)

The goal of a well designed and operated chilled beam system is to obtain even temperature distribution throughout the space and avoid drafting (too fast air movement). To achieve this, PACIFIC chilled beams include The ADC (Anti Draught Control) as a standard feature. They are an option for the PACIFIC HC.

ADC consists of a number of sections with adjustable fins arranged in the outlet of the unit with a simple grip of the hand, the fins can be set to an appropriate angle to direct the discharge air and in this way create the desired air distribution pattern. The standard setting for ADC is straight but the unit can be supplied factory-preset to a V-shape distribution pattern if desired

Anti Draught Control (ADC)

ADC set to the V-shape setting

Certification

The Swegon PACIFIC and PACIFIC HC are Eurovent certified, which is your guarantee that all specified data has been confirmed by tests and has been validated. This includes data provided in Swegon’s selection software, ProSelect Web. Click here to learn more about Chilled Beam Certification.

In Addition, the PACIFIC and PACIFIC HC chilled beams are certified by Intertek to UL 1995- Heating and Cooling equipment and CAN/CSA C22.2.

Applications

Standard PACIFIC

PACIFIC HC

PACIFIC and PACIFIC HC are designed to be installed in suspended ceilings, drywall ceilings, clouds or suspended pendant style. The PACIFIC and PACIFIC HC design module (faceplate) is designed to fit in most standard ceiling grid systems. Customized modules are available for integration in most suspended ceiling systems available in the market.

- T-section grid systems, imperial (NA), 24 in center-to-center

- T-section grid systems, 600 mm center-to-center

- T-section grid systems, 625 mm center-to-center

- T-section grid systems, 675 mm in center-to center

- Sheet-metal modular ceiling

- Strip grid systems

- Drywall ceiling (requires separate accessories)

Hinged face plate.

The PACIFIC and PACIFIC HC face plate is hinged and can be swung out from either side to a 90-degree open position. This completely exposes the coil for cleaning. Safety cords secure the face plate and ensure that is cannot fall down.

PACIFIC HC Chilled Beam

The PACIFIC HC (High Capacity) chilled beam can deliver more primary air to the space which can be beneficial for spaces such as laboratories. The high primary airflow can also lead to increased cooling capacity per beam which can assist in spaces with high internal heat gains such as computer rooms and dry laboratories.

Standard PACIFIC Chilled Beam

The Standard PACIFIC Chilled beam is designed with an ultra-low profile to fit in small ceiling spaces. For new construction, reduced ceiling space can significantly reduce construction costs by lowering the overall building height. For retrofit construction, the PACIFIC chilled beam call allow higher suspended ceilings improving the aethetics and occupant experience.

Standard PACIFIC Design module and Capacity module

The Standard PACIFIC chilled beam is supplied as a single unit but the Capacity Module and Design Module can be independently selected.

Standard PACIFIC with Built-in access panel using shorter capacity module

In certain cases it can be advantageous to select a design module that is extra-long in relation to the capacity module. One typical case is when the beam is installed in a drywall ceiling and there is a need for inspecting the valves and/or the commissioning damper. By employing a design module that is longer than the capacity module there is built-in access to the air and water connections and controls. The inactive section of the design module is covered to avoid acoustic disturbance and to conceal the space above the false ceiling from occupants of the room.

The capacity module is always installed offset toward the one end panel with the water connection on the side where the inactive section is situated.

Standard PACIFIC Chilled Beam with continuous Linear Look

The ability to choose the Design and Capacity Modules separately allows a cost effective means for create a linear look in the ceiling. The design models can be run continuously across the room awhile the Capacity models are only placed wither they are needed. This look can be accomplished in suspended ceiling, open ceilings or clouds.

PACIFIC SA/EA Option

Pacific SA/EA Option

The Standard PACIFIC chilled beam has the Supply Air/ Extract Air (SA/EA) option. The SA option allows additional primary air to be delivered to the space via the diffuser component of the chilled beam. For example, conference rooms may require increased primary air during high occupancy for improved indoor air quality and humidity control. A VAV damper in conjunction with the SA option can be used to deliver the additional ventilation air without required a diffuser in the space..

The left image shows a PACIFIC chilled beam with SA feature to deliver additional ventilation air; the Right image shows unsightly additional diffusers for increased ventilation air.

The R/A feature allows the design module to act as a return air grille and can be used in open ceiling return or duct return designs. In either case, an unsightly return air grille can be avoided by providing a clean ceiling design.

PACIFIC Chilled Beams with Coanda Wings

PACIFIC Chilled Beam with Coanda Wings

To maintain the Coanda effect when the PACIFIC and PACIFIC HC chilled beams are used in an open ceiling concept, optional Coanda wings can be supplied. The wings help ensure proper airflow and mixing to maintain a comfortable environment even when there is no ceiling for the air to travel along.

To maintain the Coanda effect when the PACIFIC and PACIFIC HC chilled beams are used in an open ceiling concept, optional Coanda wings can be supplied. The wings help ensure proper airflow and mixing to maintain a comfortable environment even when there is no ceiling for the air to travel along.

LEARN MORE

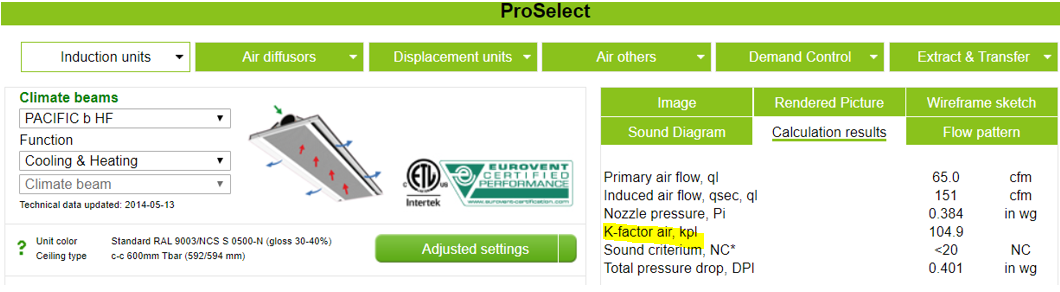

Swegon ProSelect Software

Web-based software for easy dimensioning and selection of room products: induction units, air diffusers, displacement units and products for demand-controlled ventilation.

Recommended limit values – water

| Max recommended operating pressure: | 232 PSI |

| Max. recommended test Pressure: | 348 PSI |

| Min. cooling water flow*: Capacity module: L=86.6, 106.3 in |

0.7 GPM |

| Min. permissible heating water flow*: | 0.21 GPM |

| Chilled Water Delta T | 3.6 – 9°F |

| Hot Water Delta T | 9 – 18°F |

| Min, supply flow temperature: | Should always be sized to avoid condensation |

| Max. permissible inlet flow temperature: | 140°F |

*Min. recommended water flows to ensure the entrainment of any air pockets in the circuit.

Recommended limit values – air

| Max. recommended inlet pressure: | 0.75 in WG |

| Max. recommended nozzle pressure: | 0.2 in WG |

Installation Details

PACIFIC chilled beams installed in a suspended ceiling

The PACIFIC is designed for installation flush-mounted in the majority of false ceilings available in the market.

T-section grid systems with IP units (NA)

- Width: 23.70 in

- Lengths: 47, 70.6, 94.3 and 117.9 in

T-section grid systems with 600 mm c-c and gypsum ceiling

- Width: 592 mm

- Lengths: 1194, 1715, 1794, 2394, 2994 mm

T-section grid systems with 625 mm c-c

- Width: 617 mm

- Lengths: 1242, 1867, 2492 mm

T-section grid systems with 675 mm c-c

- Width: 667 mm

- Lengths: 1342, 2017, 2692 mm

Clip-in ceiling / sheet metal modules 598 in

- Lengths: 1198, 1498, 1698, 1715, 1798, 2398, 2998 mm

PACIFIC hanging bracket

PACIFIC drywall plaster flange kit

A drywall plaster flange kit is available for installing Pacific Chilled Beams in a dry wall ceiling. The kit snaps to the chilled beam hiding the plaster edge and providing a clean, finished look.

Standard PACIFIC Air and Water Connections

Example with straight air and vertical water connections

Example with air and water connections from the side

Example with straight horizontal air and water connections

Example with of beam suspension with threaded roots

Example of beam suspension with mounting strips

The Standard PACIFIC chilled beam can have the primary air connected to either end and is field selectable. The Connection sizes are 4”, 5” and 6” round depending on the beam size.

The beam can be 2 pipe or 4 pipe depending on the application. The water connections are 12 mm or ½ NPT. Steel braided hoses with 12 mm push on for the chilled beam connection are a common means to connect to the beam. The building connection can be NPT or compression fitting as required. Click here for other chilled beam accessories

Standard PACIFIC with Primary Air Tee Connection and SA/EA Option

End connections allow a single branch duct to connect to two beams reducing the required ductwork and lowering installation cost.

PACIFIC HC Air and Water Connections

PACIFIC HC Air Connections

The PACIFIC HC air connections are center side and can be field changed to center top. Top connections are advantageous when the plenum height allows the ductwork to pass over the top of the chilled beams and a flex connection can be used from the bottom of the duct to the top of the chilled beam reducing fittings and first cost. The connection size is 5”, 6” or 8” round depending on the beam size.

The beam can be 2 pipe or 4 pipe depending on the application. The water connections are 12 mm or ½ NPT. Steel braided hoses with 12 mm push on for the chilled beam connection are a common means to connect to the beam. The building connection can be NPT or compression fitting as required. Click here for other chilled beam accessories

PACIFIC HC Water Connections

Find Documents

You can find more documents on our document search page.

Dimensions

Click on the tabs below to learn more

| A | B | C | ||

|---|---|---|---|---|

| Unit Length* | Coil Length ** | Dry Weight | Weight of Cool Water | Weight of Hot Water |

| 4′ | 4′ | 36 | 2.4 | 0.7 |

| 6′ | 4′ | 41 | 2.4 | 0.7 |

| 6′ | 6′ | 50 | 3.3 | 0.1 |

| 8′ | 6′ | 50 | 3.3 | 0.1 |

| 8′ | 8′ | 69 | 4.6 | 0.1 |

| 10′ | 8′ | 74 | 4.6 | 0.1 |

| 10′ | 10′ | 84 | 5.8 | 1.5 |

| L – Unit Length | ||||

|---|---|---|---|---|

| Nominal Length FT | 4′ | 6′ | 8′ | 10′ |

| Order Code | 1213 | 1823 | 2433 | 3043 |

| Actual Length IN (“) | 47.76 | 71.77 | 95.79 | 119.80 |

| C – Unit Length | ||||

|---|---|---|---|---|

| Nominal Length | 4′ | 6′ | 8′ | 10′ |

| Order Code | 1100 | 1600 | 2200 | 2700 |

| Actual Length IN (“) | 43.5 | 64.4 | 87.1 | 107.9 |

| a – access | 3.2 | 6.4 | 7.7 | 10.9 |

| Nominal Length | Availability, L – Unit Length | |||

| 4′ | 6′ | 8′ | 10′ | |

| 4′ | ⊗ | |||

| 6′ | ||||

| 8′ | ||||

| 10′ | ||||